Manipulator Robotics Introduction

Notes of book Introduction ot Robotics Mechanics and Control.

Content

Focus on mechanical manipulator type of robot.

Table of content

- Introduction

- Describe pose in 3D

- Position & rotation

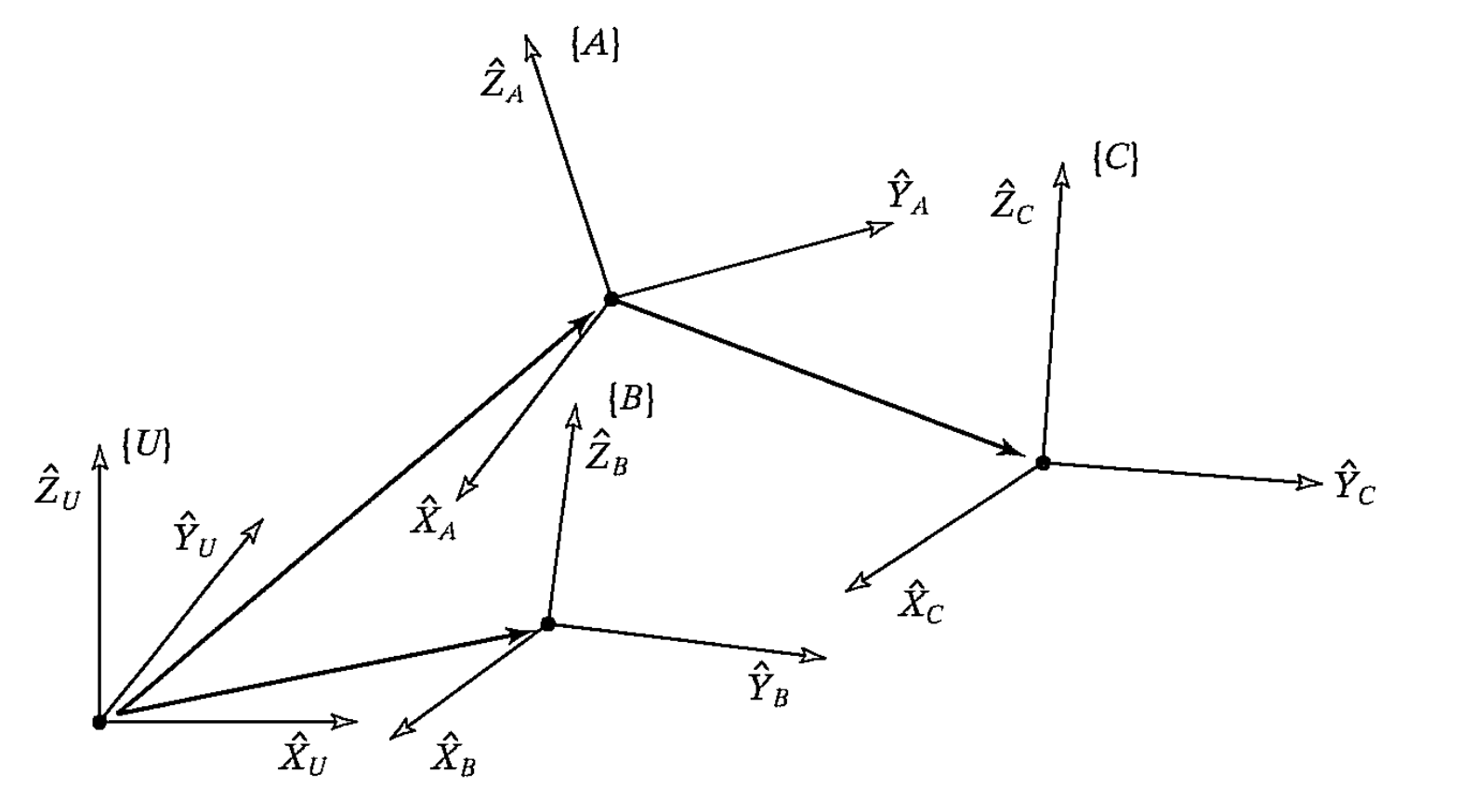

- Attach a coordinate system or frame to an object, then describe its pose w.r.t other reference coordinate systems

- Geometry of mechanical manipulators. Static Kinematics

- Manipulator

- consist of rigid links, which are connected by joints

- joint angles (rotation), joint offset (translation)

- tool frame is attached to end-effector

- base frame is attached t o nonmoving base of manipulator

- Kinematics

- Treats motions without regard to the forces which cause it

- Study time-based properties of the motion

- Forward kinematics of manipulator

- Given a set of joint angles, compute the pose of tool frame w.r.t the base frame

- Inverse kinematics of manipulator

- Given the pose of end-effector of the manipulator, calculate all possible sets of joint angles

- non-linear optimization problem

- Manipulator

- Kinematics with velocities and static forces

- Jocobian of manipulator

- mapping from velocities in joint space to Cartesian space

- singularity of the mechanism

- mechanism become locally degenerate and behaves as if it only has 1 DoF

- Jocobian of manipulator

- Manipulator dynamics

- Study forces required to cause motion

- Motion of manipulator. Trajectory in space

- Trajectory generation

- spline: refer to a smooth function and passes through a set of via points

- Trajectory generation

- Mechanical design

- How to design a manipulator, including its mechanical structure, attached sensors

- linear/non-linear control theory

- actuator perform torque on the joint

- position and velocity sensors are monitored by control algorithm

- linear control

- linear approximations to the dynamics of a manipulator

- non-linear control

- consider nonlinear dynamics

- Active fore control

- Force control vs position control

- Programming robots

- Off-line simulation

Notation

- $A$: vector or matrix

- $a$: scalars

- $^A P$: position vector under coordinate system {A}

- $^A_B R$: rotation matrix {B} relative to {A}. $$^A P = ^A_B R ^B P $$

- Vectors are taken to be column vectors

Spatial Descriptions and transformations

- Position under universal coordinate frame {A}. $^A P$

- $^A P_{BORG}$ is the vector from frame {A} to frame {B} origin, and expressed under frame {A}

- Rotation matrix (3x3), frame {B} relative to frame {A}

$$

^A_B R = [^A \hat{X}_B, ^A \hat{Y}_B, ^A \hat{Z}_B]

$$

where $^A \hat{X}_B, ^A \hat{Y}_B, ^A \hat{Z}_B$ are the coordinate of unit axes vectors of frame {B} in frame {A}. Row vectors are the axes vectors of frame {A} in frame {B} since $^B_A R = ^A_B R^{-1} = ^A_B R^T$

- Maps position from frame {B} to frame {A}

$$

^A P = {^A_B R} {^B P} + ^A P_{BORG}

$$

or in homogenous coordinate, write as $^A_B T$ - Transformation operators. Not transforming the frame, move the point under the same frame instead

$$

^A P_2 = T {^A P_1}

$$

The transform that rotates by $R$ and translate by $Q$ is the same as the transform that describes a frame rotated by $R$ and translated by $Q$ relative to the reference frame. - Other rotation forms

- 3 rotations taken about fixed axes (fixed-angle sets) yield the same final orientation as the same three rotations taken in opposite order about the axes of the moving frame (Euler-angle sets).

- Equivalent angle-axis representation $R_K(\theta)$. Rotating around unit vector $^A \hat{K}$ by $\theta$

- Euler parameters. Unit quaternion

- Different vectors

- line vector: dependent on its line (or point) of action to cause its effect

- free vector: only its direction and magnitude matters, can be placed in anywhere in space

- Reduce computation

- Compare matrix calculations vs matrix vector calculations

- Calculate first 2 columns, use cross product to get the third column

Manipulator Kinematics

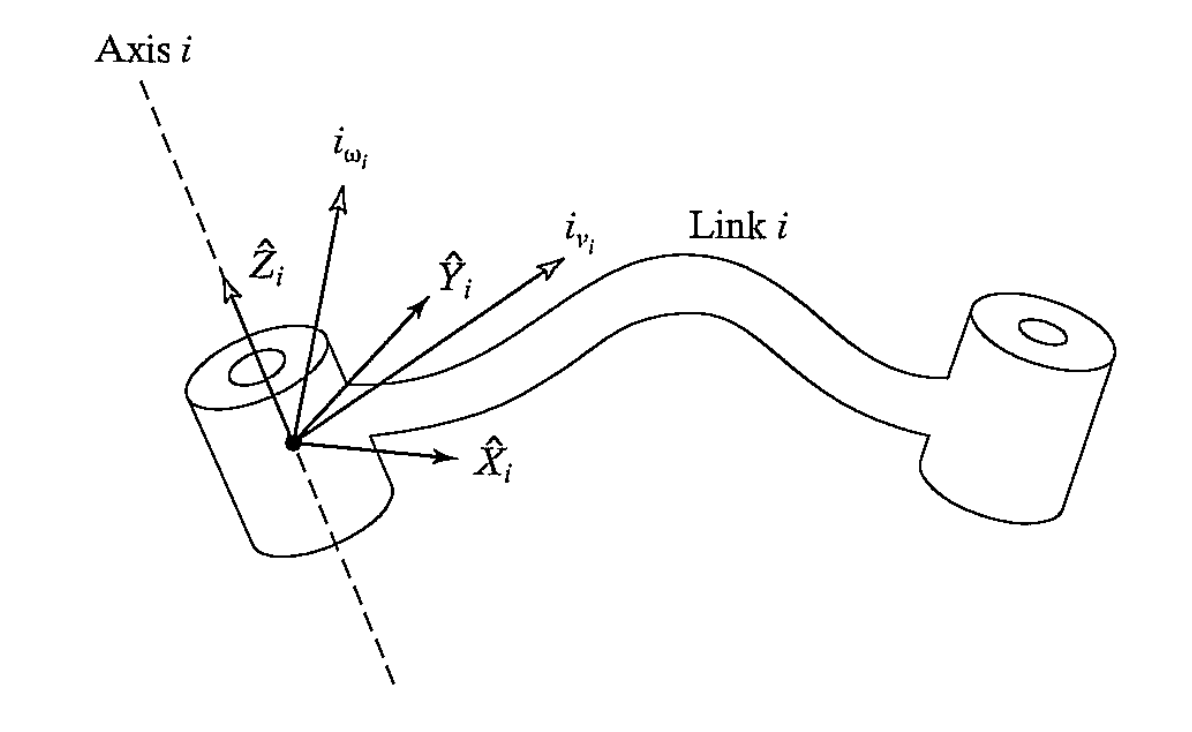

Joints, Links

- joint axis: revolute or prismatic

- joint 1 is the first movable joint in the robot

- joint n is the last movable joint in the robot

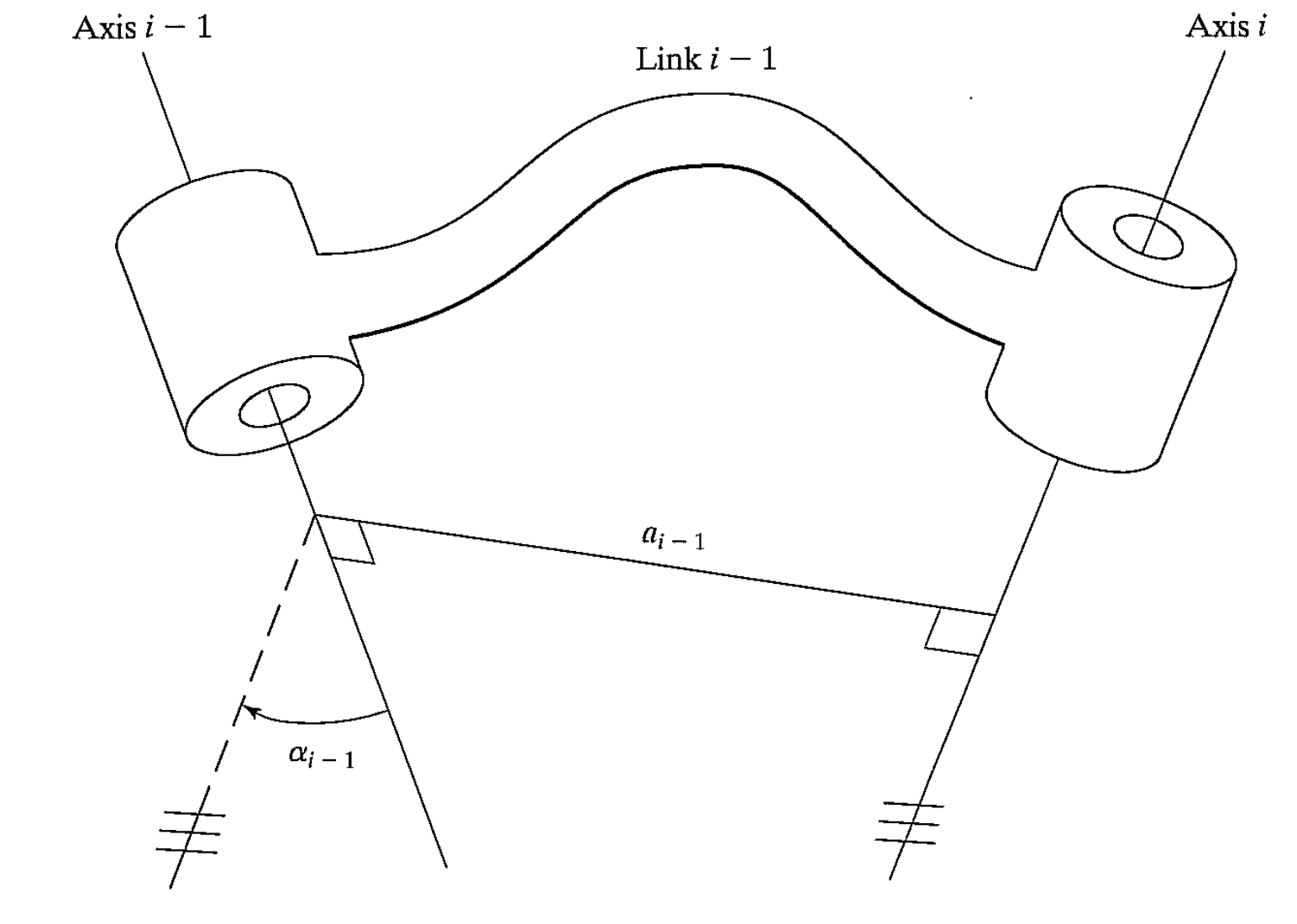

- link: the arm. link $i$ is from axis $i$ to axis $i+1$

- link 0 is from the non-moving base of the robot to the first movable joint

- link n is from the last movable joint to the end-effector

- link length: length of line which is perpendicular to the 2 axes (mutual perpendicular, current axe and next axe)

- $a_i$ = distance from $\hat{Z}_i$ to $\hat{Z}_{i+1}$ measured along $\hat{X}_i$

- $a_0 = 0$ because axis joint $0$ could be chosen arbitrary

- $a_n = 0$ because there is no more other joints behind

- link twist: angle in the projected plane from axis $i$ to axis $i+1$. The plane’s normal vector is $a_i$, the angle follows the right-hand law

- $\alpha_i$ = angle from $\hat{Z}_i$ to $\hat{Z}_{i+1}$ measured about $\hat{X}_i$

- $\alpha_0 = 0$ because axis joint $0$ could be chosen arbitrary

- $\alpha_n = 0$ becaus there is no more other joints behind

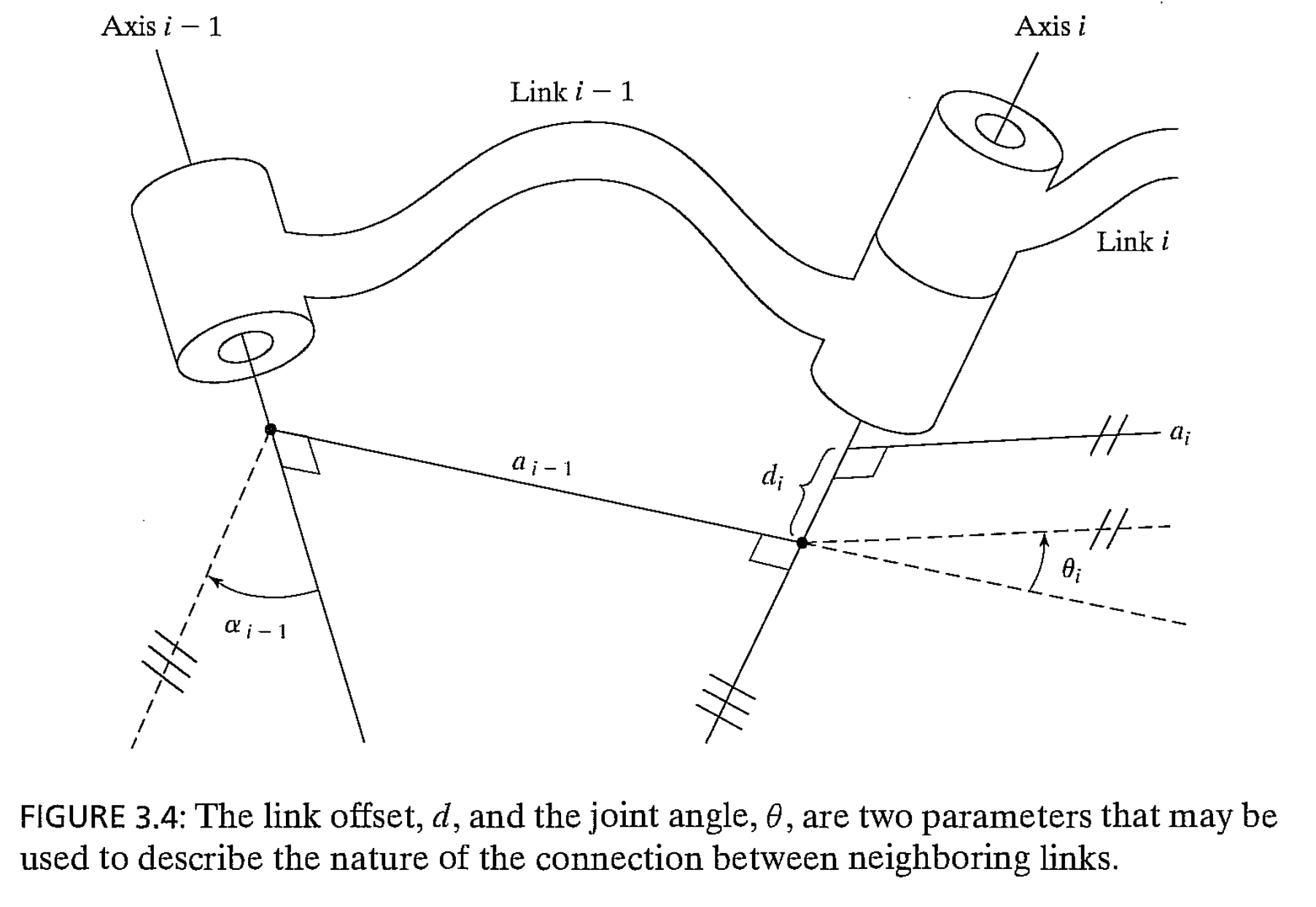

- link offset: distance between intersection of $a_{i-1}$ on axis $i$ and $a_i$ on $i$. Distance is measured along the axis $i$

- $d_i$ = distance from $\hat{X}_{i-1}$ to $\hat{X}_i$ measured along $\hat{Z}_i$

- $d_1$

- $d_1 = 0$ for revolute joint

- $d_1$ zero position could be chosen arbitrary for prismatic joint

- $d_n$ same as above

- joint angle: angle between from $a_{i-1}$ to $a_i$ around axis $i$. Also follows right-hand law

- $\theta_i$ = angle from $\hat{X}_{i-1}$ to $\hat{X}_i$ measured about $\hat{Z}_i$

- $\theta_1$

- $\theta_1$ zero position could be chosen arbitrary for revolute joint

- $\theta_1 = 0$ for prismatic joint

- $\theta_n$ same as above

- link parameters: 3 fixed parameters

- joint variable: 1 changeable parameter

- $\theta_i$ for revolute joint i

- $d_i$ for prismatic joint i

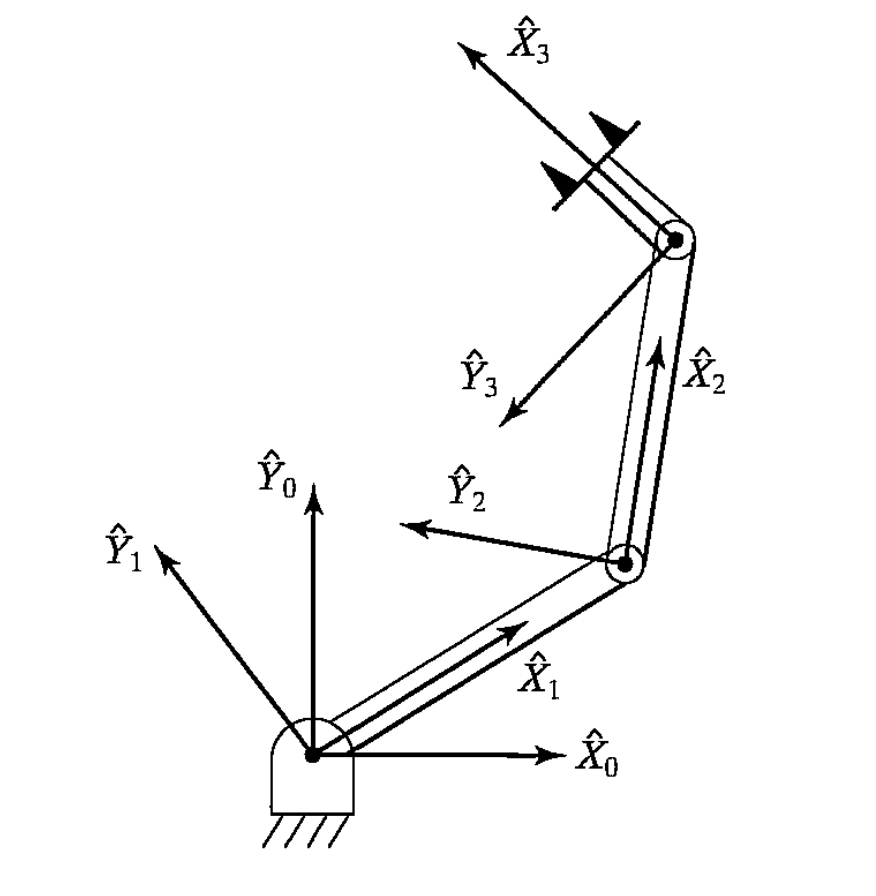

Frames

- frame {i} attach to link i (axis i)

- Origin is the intersection point of the common perpendicular line on axis $i$.

- Z-axis coincident with joint axis i

- X-axis points along $a_i$ in the direction from joint $i$ to joint $i+1$

- or orthonormal to the $Z_i, Z_{i+1}$ plane

- Frame {0} is arbitrary, but usually chose coincides with frame {1}. Frame {0} is the one stationary and serve as reference frame

- Frame {n}

- X-axis is chosen it aligns with X-axis of frame {n-1} when $\theta_n = 0$

- Origin is chosen at axis $n$ when $d_n = 0$

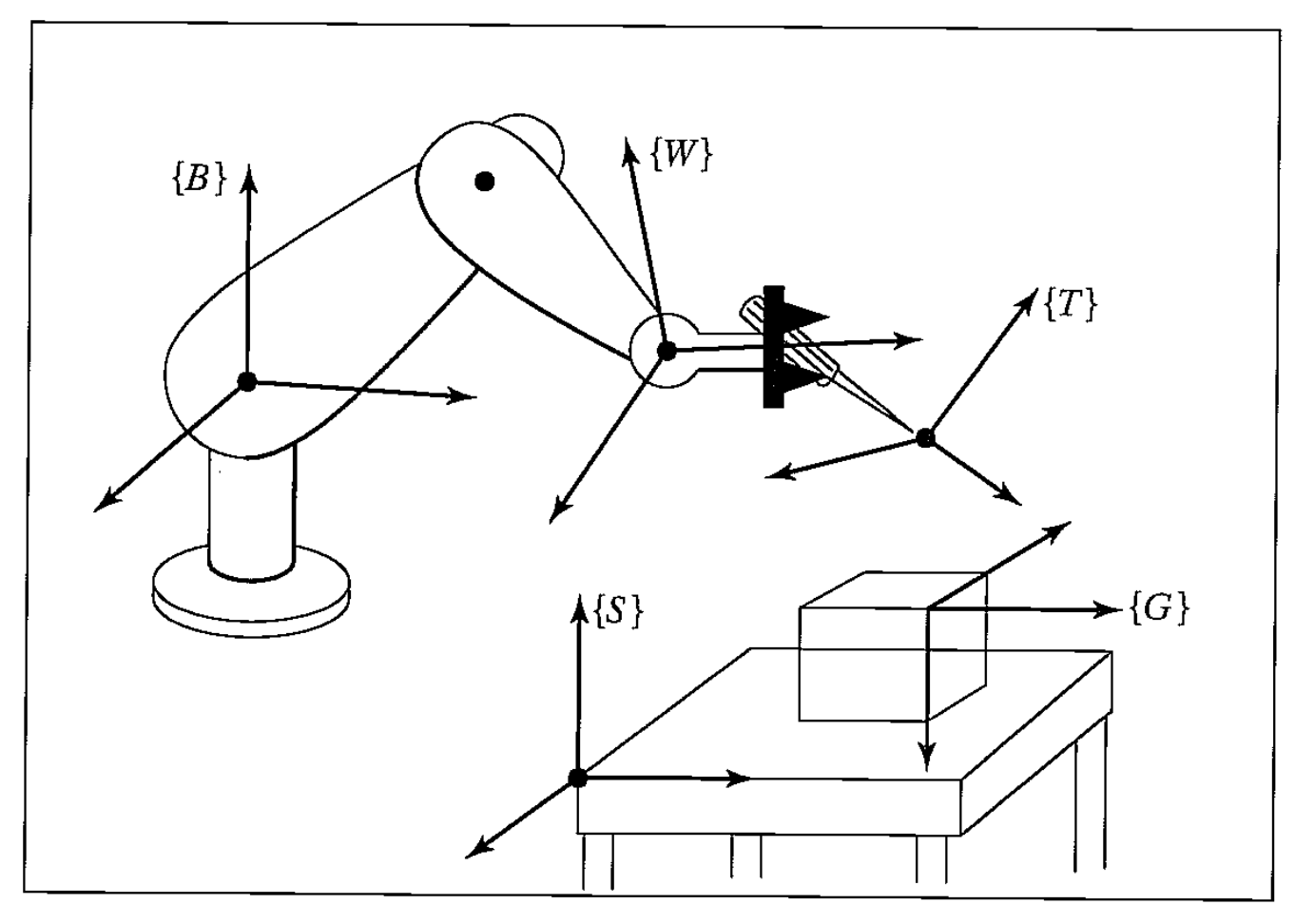

- Frame naming convention

- Base frame {B}: frame {0}, link {0}, nonmoving

- Wrist frame {W}: frame {N}, last link the manipulator. Refer as $^B_W T = ^0_N T$

- Tool frame {T}: the end of any tool held by robot, or in the middle of fingertips. Refer as $^W_T T$

- Station frame {S}: task-relevant location, task frame, world frame, universal frame. Refer as $^B_S T$

- Goal frame {G}: location to which the robot is to move the tool. Tool frame and Goal frame will coincident in the end. Refer as $^S_G T$

- WHERE function

- $^S_T T = ^B_S T^{-1} {^B_W T} {^W_T T}$, present where the tool is relative to the station

- Frame kinematics transformation

$$

^{i-1}_i T=\begin{bmatrix}

\cos\theta_i & -\sin\theta_i & 0 & a_{i-1} \\

\sin\theta_i \cos\alpha_{i-1} & \cos\theta_i \cos\alpha_{i-1} & -\sin\alpha_{i-1} & -\sin\alpha_{i-1}d_i \\

\sin\theta_i \sin\alpha_{i-1} & \cos\theta_i \sin\alpha_{i-1} & \cos\alpha_{i-1} & \cos\alpha_{i-1} d_i \\

0 & 0 & 0 & 1

\end{bmatrix}

$$

$$

^0_N T = {^0_1 T} {^0_1 T} \cdots {^{N-1}_N T}

$$ - $^0_N T$ is a function of $n$ joint parameters

- Difference spaces

- actuator space: the parameters of actuators

- joint space: the space of the $n\times 1$ joint vector formed by $n$ joint variables

- Cartesian space: the relationship between different frames

- Reduce computation

- Store sin cos values into lookup table

- Store intermediate variables

Inverse Manipulator Kinematics

- What to solve: find the required joint angles to get the required $^S_T T$

- $^B_S T, ^W_T T$ are known

- Find required joint angles to get the required $^B_W T = ^0_N T$

- Workspace: the volume of space that end-effector of manipulator can reach

- Dextrous workspace: volume of space that end-effector can reach with all orientations

- Reachable workspace: volume of space that end-effector can reach in at least one orientation

- But we usually care about the workspace of wrist frame {W} instead of the end-effector tool frame {T} since $^W_T T$ is known

- Workspace is a subset of the n-DoF subspace, where subspace is the reachable workspace without constraints of parameters

- Solvable of inverse Kinematics

- Solution existence = desired position and orientation of wrist frame {W} is in the workspace

- Multiple solutions = desired position and orientation of wrist frame {W} is in the Dextrous workspace

- 6 DoF manipulator could have up to 16 possible solutions

- Proved: all systems with revolute and prismatic joints having 6 DoF in a single series chain are solvable

- But solution is in numerical

- Closed-form solutions of 6 DoF is solvable in special cases

- e.g. 3 neighboring joint axes intersect at a point

- Method of solution

- numerical solutions: iterative method, slow, not guaranteed to find all solutions

- closed-form solutions

- construct the desired $^B_W T$ matrix (subspace) according to the required position and orientation

- construct equations between the constructed $^B_W T$ and kinematics matrix

- replace sin cos with single variable $u$, to convert transcendental equations to polynomial equations

- Proved. Polynomials up to degrees 4 could be solved in closed form

- forms triangles

- Special cases

Pieper’s solution

- Any 3 DoF manipulator’s closed-from solution can be solved

- Compute a modified goal frame $^S_{G\prime} T$ such that $^S_{G\prime} T$ lies in manipulator’s subspace and is “near” to $^S_G T$

- Compute inverse kinematics for $^S_{G\prime} T$

Pieper’s solution to get closed-form solution

- Solve for first 3 joints given the position of the origin of frame {4} {5} {6}

- Solve for the later 3 joints given the orientation

Jocobians: velocities and static forces

Linear and angular velocities

- Linear velocity vector for a point

$$

^A(^B V_Q) = {^A_B R} {^B V_Q} = \frac{^A d}{dt} {^B Q} = {^A_B R} \lim_{\Delta t \rightarrow 0} \frac{^B Q(t+\Delta t) - {^B Q(t)}}{\Delta t}

$$

is the velocity of position vector Q whose differentiation is done in frame {B} and finally expressed in frame {A}. - Short write cases

- $v_c = {^U V_{CORG}}$ is the velocity of origin of frame {C} differentiation in reference frame {U}

- $^A v_c$ is the above velocity but expressed in frame {A}

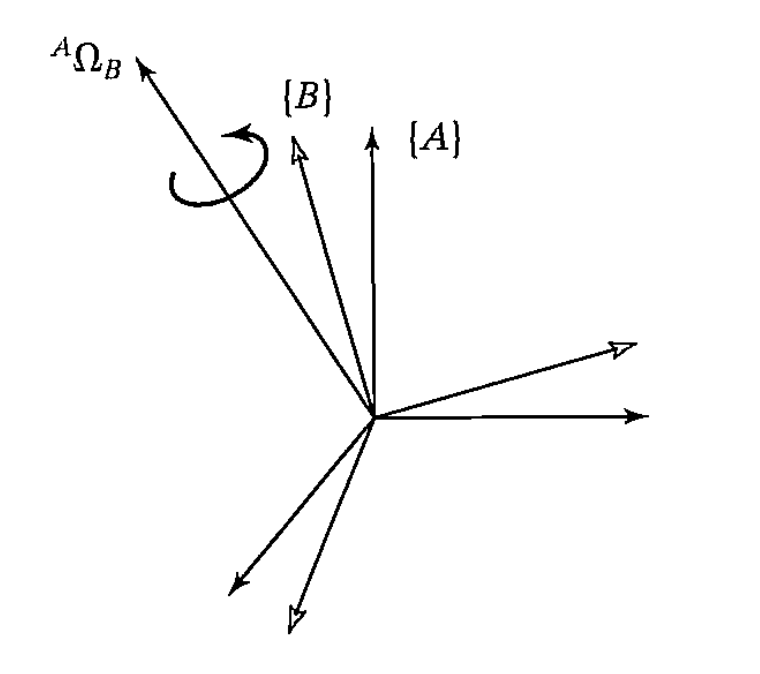

- Angular velocity vector for a body

$$

^C ({^A \Omega_B})

$$

is the rotation of frame {B} relative to frame {A}, and finally expressed in frame {C}- The direction of vector is the rotation axis

- The magnitude of vector is the current speed of rotation

- Short write cases

- $w_c = {^U \Omega_C}$ is the angular velocity of frame {C} relative to reference frame {U}

- $^A w_c$ is the above angular velocity but expressed in frame {A}

Simultaneous linear and rotational velocity

$$

^A V_Q = {^A V_{BORG}} + {^A_B R} {^B V_Q} + {^A\Omega_B} \times {^A_B R} {^B Q}

$$- where frame {A} is the reference frame and fixed

- frame {B} has both linear velocity $^A V_{BORG}$ and rotational velocity $^A \Omega_B$

- point Q also has a linear velocity $^B V_Q$ in frame {B}

Velocity of link i is given by vector $v_i$ and $w_i$, which are gotten relative to frame {0} and can be expressed in any frame

velocity propagation: velocity of link i+1 is velocity of link i, plus new velocity components added by joint i+1

$$

\begin{aligned}

^{i+1} w_{i+1} &= {^{i+1}_i R} {^i w_i} + \dot{\theta}_{i+1} {^{i+1} \hat{Z}_{i+1}} \\

^{i+1} v_{i+1} &= {^{i+1}_i R} ({^i v_i} + {^i w_i} \times {^i P _{i+1}} )

\end{aligned}

$$where

- $\dot{\theta}_{i+1} {^{i+1} \hat{Z}_{i+1}} = ^{i+1} \begin{bmatrix} 0 \\ 0 \\ \dot{\theta}_{i+1} \end{bmatrix}$

- $^i P_{i+1}$ is the coordinate of origin of frame {i+1} in frame {i}

$$

\begin{aligned}

^{i+1} w_{i+1} &= {^{i+1}_i R} {^i w_i} \\

^{i+1} v_{i+1} &= {^{i+1}_i R} ({^i v_i} + {^i w_i} \times {^i P _{i+1}} ) + \dot{d}_{i+1} {^{i+1} \hat{Z}_{i+1}}

\end{aligned}

$$where $\dot{d}_{i+1} {^{i+1} \hat{Z}_{i+1}} = ^{i+1} \begin{bmatrix} 0 \\ 0 \\ \dot{d}_{i+1} \end{bmatrix}$

Velocity transformation

$$

\begin{aligned}

^A v_A &= {^A_B T_v} {^B v_B} \\

\begin{bmatrix}

^A v_A \\

^A w_A

\end{bmatrix}

&=

\begin{bmatrix}

^A_B R & {^A P_{BORG}} \times {^A_B R} \\

0 & {^A_B R}

\end{bmatrix}

\begin{bmatrix}

^B v_B \\

^B w_B

\end{bmatrix}

\end{aligned}

$$

Jocobian

- Equation

$$

^0 v = {^0 J(\Theta)} \hat{\Theta}

$$

where- $^0 v = \begin{bmatrix} {^0 v} \\ {^0 w} \end{bmatrix}$ is the Cartesian velocities of the link n expressed in frame {0}

- $\hat{\Theta}$ is the vector of joint velocity

- ${^0 J(\Theta)}$ is the Jocobian matrix, which represents the derivate of each term of Cartesian position and orientation on each term of joint angle. Its value changes as the joint angles change.

- Changing frame

$$

{^A J(\Theta)} = \begin{bmatrix}

{^A_B R} & 0 \\

0 & {^A_B R}

\end{bmatrix}

{^B J(\Theta)}

$$ - Inverse of the Jocobian could be used to calculate joint velocities given desired Cartesian velocities of link n

- Singularities: where the joint angles make the ${^0 J(\Theta)}$ singular

- Workspace-boundary singularities: manipulator fully stretched out or folded back

- Workspace-interior singularities: caused by a lining up of 2 or more joint axes

Force and torque

- Force propagation from link to link

$$

\begin{aligned}

^i f_i &= {^i_{i+1} R} {^{i+1}} f_{i+1} \\

^i n_i &= {^i_{i+1} R} {^{i+1}} n_{i+1} + {^i P_{i+1}} \times {^i f_i}

\end{aligned}

$$

where- $f_i$ is force exerted on link i by link i-1

- $n_i$ is torque exerted on link i by link i-1

- Torque for joint

- For revolute joint

$$

\tau_i = {^i n_i^T} {^i\hat{Z}_i}

$$ - For prismatic joint

$$

\tau_i = {^i f_i^T} {^i\hat{Z}_i}

$$

- For revolute joint

- Jocobian

$$

\tau = {^0 J^T} {^0 \mathcal{F}}

$$

where $\mathcal{F}$ is the Cartesian forces acting at the hand, and $\tau$ is the joint torques - Force transformation

$$

\begin{aligned}

^A \mathcal{F}_A &= {^A_B T_f} {^B \mathcal{F}_B} \\

\begin{bmatrix}

^A F_A \\

^A N_A

\end{bmatrix}

&=

\begin{bmatrix}

^A_B R & 0 \\

{^A P_{BORG}} \times {^A_B R} & {^A_B R}

\end{bmatrix}

\begin{bmatrix}

^B F_B \\

^B N_B

\end{bmatrix}

\end{aligned}

$$

and

$$

{^A_B T_f} = {^A_B T_v^T}

$$

Trajectory generation

- Motions is tool frame {T} relative to station frame {S}

- To generate a trajectory of motions

- Spatial constraints: Path points

- a set of intermediate frames that the tool frame should reaches

- including initial, target point, and via points

- Temporal attributes: the time between points

- Spatial constraints: Path points

- In order to make the trajectory smooth, the function of the trajectory and its first derivate should be continuous

- Convert path joints to joint angles by inverse kinematics

- For each 2 path points, fit a function of the joint angles

- Cubic polynomial

- 4 entries since each 2 path points provides 4 constraints (2 position constraints, 2 velocities constraints)

- $\theta(t) = a_0 + a_1 t + a_2 t^2 + a_3 t^3$

- Constraints of each 2 point

$$

\begin{aligned}

\theta(t_0) &= theta_0 \\

\theta(t_1) &= theta_1 \\

\dot{\theta}(t_0) &= v_0 \\

\dot{\theta}(t_1) &= v_1

\end{aligned}

$$ - Higher-order polynomials

- Quintic polynomial (5 degree, 6 entires), enabling specify position, velocity, and acceleration.

- Linear function with parabolic blends

Reference

- Rodd, Michael G. “Introduction to robotics: Mechanics and control: John J. Craig.” (1987): 263-264.